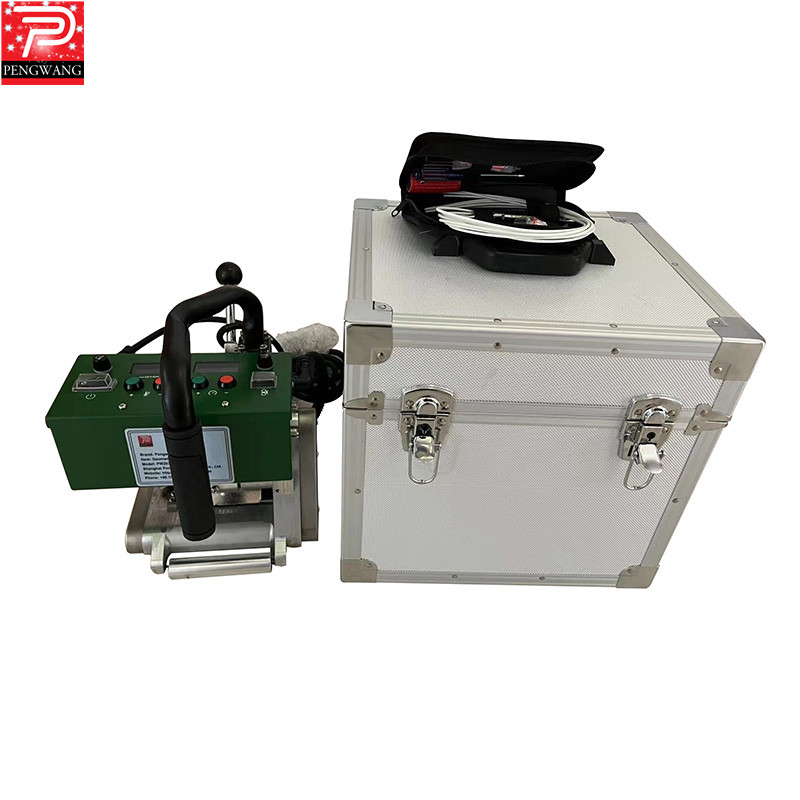

ur_here home > Products > Geomembrane welder > Pengwang PWGM2 Double Side Welding applied for 0.2-2mm Material

Power:1200W Voltage: 220V/110V Frequency: 50Hz Welding speed: 0.5-10m/min Heating temperature: 0-450℃ Material thickness: 0.2-2.0mm Welding seal thickness: 15mm×2, Intermediate cavity:20mm Seam strength: ≥85% base material (tensial resistance in share direction Joint width: 120mm N.W.: 7.5kg; G.W.:13kg Insulation grade: I

PWGM2 Series Thick Geomembrane Welder adopts advanced hot wedge structure, with high power, high speed and strong pressure force; suitable for 0.2-2mm thickness hot melt materials such as PE, PVC, HDPE, EVA, PP, TPO. This welder is extensively used in highway/railway tunnels, urban subway, aquaculture, water protection, chemical mining, refuse landfill, sewage treatment, waterproofing projects etc.

Tips:

a. For welding membrane thickness 0.2-0.75 mm with silicone pressure roller.

b. For welding membrane thickness 0.75-2 mm with steel pressure roller.

c. For welding the materials that may release corrosive gas after hot fusing such as PVC and other similar material, stainless steel hot wedge (optional accessory) is preferred for extending of service life.

d. Only PWGM2 is the double welding, it means two membranes put into together to weld.

e. Any else customized demands, you can ask us directly, we have a professional technicians team.

➪Related product: PW900 Geomembrane welder

Tips:

a. For welding membrane thickness 1.0-3.0 mm with steel pressure roller.

b. For welding the materials that may release corrosive gas after hot fusing such as PVC and other similar material, stainless steel hot wedge (optional accessory) is preferred for extending of service life.

c. Any else customized demands, you can ask us directly, we have a professional technicians team.

➪Rated product: PW900D Geomembrane welder

Tips:

a. For welding membrane thickness 1.0-3.0 mm with steel pressure roller.

b. For welding the materials that may release corrosive gas after hot fusing such as PVC and other similar material, stainless steel hot wedge (optional accessory) is preferred for extending of service life.

c. Any else customized demands, you can ask us directly, we have a professional technicians team.

d. With the temperature display and speed display screen at the same time.

➪Related product: PW202 Geomembrane welder

Tips:

1. The silica pressure roller is suitable for welding membrane which the thickness below 0.5-2mm.

2. The steel pressure roller is suitable for welding membrane which the thickness between 1.0-3.0mm.

3. Max. temperature can be reached to 800℃.

4. Break traditional 23kg heavy weight, it's just 9kg light body weight, which makes the welding is more convenient.

➪Related product: PW102 Digital Display Welder

Tips:

1. For welding membrane with thickness below 1.0 mm, the silica pressure roller is the suitable choice.

2. For welding membrane with thickness above 1.0mm, the steel pressure roller is the best choice.

3. Any customized demands, you can ask us directly. We have professional technicians team.

Pengwang PWGM1 Geomembrane Welder▼

Pengwang PW900 Geomembrane Welder▼

Pengwang PW202 Geomembrane Welder▼

Pengwang PW102 Geomembrane Welder▼

Pengwang PW602A Metabo Double Heating Extruder▼

Pengwang PW801 Digital Display Hot Air Blower▼

Model | GM2 |

Power | 1200W |

Voltage | 220/110V |

Frequency | 50/60Hz |

Welding speed | 0.5-10m/min |

Heating temperature | 0-600℃ |

Material thickness | 0.2-2mm |

Welding seal thickness | 15mm×2 |

Intermediate cavity: | 20mm |

Seam strength | ≥85% base material (tensial resistance in share direction) |

Joint width | 120mm |

N.W. | 7.5kg |

G.W. | 13kg |

Insulation grade | I |

PWGM2 is double side welding, it means two membranes put into together to weld. It's mainly used in waterproofing projects, such as round tank, biogas digester etc.

mary.gao@pwwelder.com; alice.wang@pwwelder.com

+86 15801732387; +86 18221372093

Building 8, No. 1098, Chuansha Road, Pudong New Aera, Shanghai, China